First day of the workshop, after staying the night here at Waugh Mountain Alpaca Farm.

Quite a bit of kit here that comes along with the price of the workshop, though Caroline almost wasn’t able to participate on relatively short notice. These looms are custom-made by Janie’s husband using copper pipes (Janie was the host of the natural dying workshop a couple of weeks ago). After leaving Blue, Janie notified us that enough parts were still on hand that one of these custom tapestry looms could still be made, so she was in.

While I already know the reality, it doesn’t mean I can’t wish that someday I’ll meet an alpaca that runs up and wants to snuggle as badly as I do

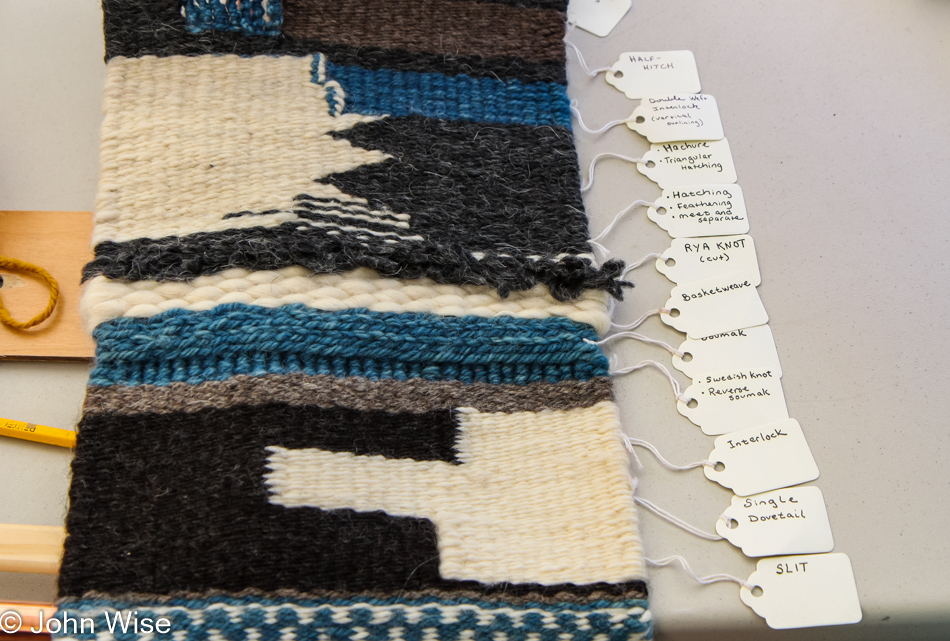

This is the example loom that Janie already started to give the attendees an idea of how things look and inspire them that this is exactly what they’ll be doing.

Maybe this is a standard operating procedure, but having this running sample of the different weaving techniques is genius to me.

Who knew that there were so many techniques for weaving fabric?

Placing her first thread ever on a tapestry loom, and my wife is already an expert. That’s a half-twit eccentric wife weft with a doublecross wiggly knot. I’m impressed.

This is my favorite part of every workshop, lunch. The story from this point on deviates as Caroline and company continue on with the technical details in learning the fine art of tapestry weaving while I took a road trip north.

I’m up in Sanders, Arizona, at the R.B. Burnham & Company Trading Post.

My two-hour drive was to check out the churro wool offerings that might be used in future Navajo rug weavings. I also bought some weaving forks and a hip spindle to surprise Caroline. As for what she actually accomplished at the workshop today, I have no idea, and she didn’t take photos, so this is the end of this post.

[Sad to say, I think that loom sits in the closet as it was when we left the workshop, so technically, we could post another photo… Caroline]